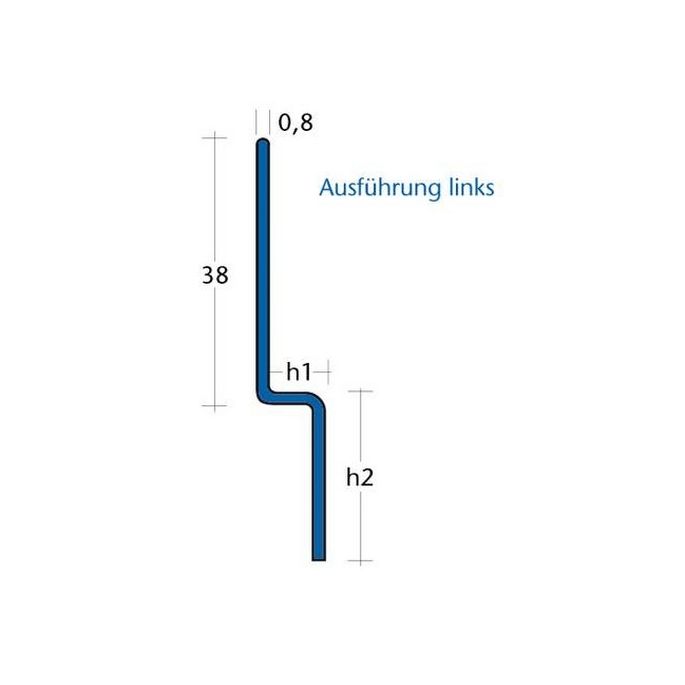

Blanke Aqua Keil Wall 8462840125L gradient edge profile 1480x12,5x32mm left Stainless steel chrome-plated

- 12

- 5mm

Blanke Aqua-Keil Wall gradient edge profile

The BLANKE AQUA-KEIL WALL stainless steel gradient edge profile for the perfect detail solution on inclined surfaces, to connect to walls when installing linear drainage. Available as a right and a left version.

h1 = 12,5mm

h2 = 32mm

Characteristics

- Easy to install – slope of 2% included

- Protective

- Decorative

- Avoids a bevel cut of the tile

- System product for BLANKE DIBA-LINE+

Description

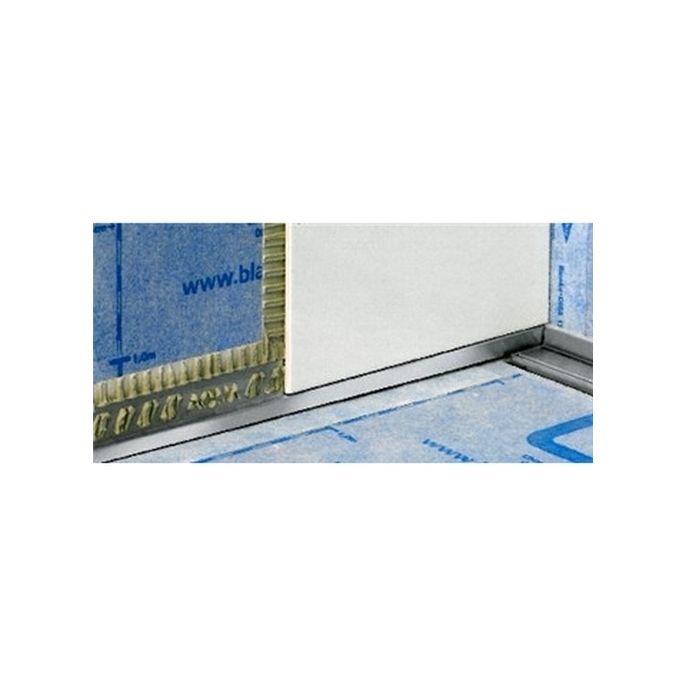

Blanke AQUA-KEIL WAND is a gradient profile in stainless steel for a slope of 2 % and a perfect solution to connect gradient areas to walls, especially when installing floor-level showers with linear drainage systems. BLANKE AQUA-KEIL WALL is available in left and right versions.

Aplication area

Blanke AQUA-KEIL WALL is usable as perfect solution to connect areas between levelled floorings and wall areas for accessible showers where a linear drainage system is used.

Working instructions

Press in the perforated setting leg of BLANKE AQUA-KEIL WALL into the fresh adhesive bed and bring it into the correct position. Then press in the next tiles which have to be moved into to right position so that the top of the profile is flushing with the tiles. There should be a gap next to the tile of ca. 1,0 - 1,5 mm. The gab has to be filled

in completely with mortar.

In case that the profile has to be cutted do it always at the widest point.

For cleaning the stainless steel do not use any steel wool or steel brush. Thereby extraneous rust could occur. Any cleaning agents must not contain hydrochloric acid or chlorine.